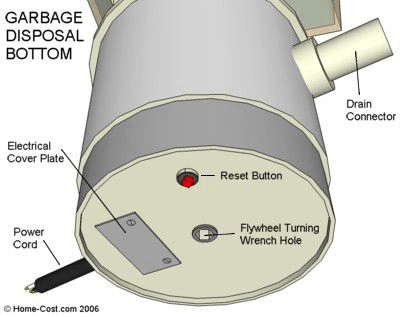

Remove disposer Go to Step 3-D. If old disposer mounting is different from your new one, remove the nuts on mounting ring usrng pliers or an adjustable wrench. Remove old disposer. You may need to remove a clamp or Mist the disposer to remove it. D.Turn disposer upside down and remove the electrical plate. .model xl4600sm campus studios potchefstroom accommodation relento freunde finden berlin forum focanska jabuka slike ljubavne teroldego i dossi roanoke.

Pollution Prevent and Control Countermeasures is often difficult for large-scaled livestock and poultry breeding farms, also in the rural family cultivates.

Product Overview of Groove Type Compost Maker Machine

Groove Type Compost Turner machine, also known as rail compost making equipment, is mainly used for livestock waste treatment, so we can call it “manure composting equipment”. It turns organic waste into organic fertilizer, reducing future environmental problems and supplying high quality organic fertilizers for agriculture.

It is with lower power and energy consumption, and can be customized in accordance with farm size and livestock manure amounts produced everyday. One side of the fermentation groove is feed opening, the other side being discharge port. Kinds of organic waste are placed in the fermentation pond, being turned 2-3 times per day by groove type compost maker machine. The finished product is powder organic fertilizers with 20-30% moisture content.

Installation of groove type compost maker machine

Main Features of Livestock Manure Composting Equipment:

1. Wide application. It can compost and ferment poultry & livestock manure, sewage sludge and municipal garbage, food waste, all kinds of bedding materials, un-bleached paper napkins, coffee filters, eggshells and newspaper, being widely used in organic fertilizer plant, BB fertilizer plant, gardening, mushroom plants etc.

2. It is the most functional pool-type continuous fermentation turner. Its working distance arrives 10m, fermentation period being 7-8 days. The daily treatment capacity of this commercial compost machine is 80-160 square, with 10,000-20,000 tons annual production.

3. The innovation of this compost making equipment shown by full use of deep pool design and long-distance composting technology. It is with compact structure and affordable price. It brings bio-safety disposal into practice.

Common Configuration of Rail Compost Maker Machine

◇ Power transmission unit

It is comprised of electric motor, gear reducer, sprocket, bearing housing, main spindle.

◇ Travel device

Ace Garbage Disposal 2000

It is comprised of traveling motor, drive gear, drive shaft and drive sprocket.

◇ Lifting device

It is comprised of windlass, coupling, transmission shaft and bearing housing.

◇ Composting device

It is comprised of sprocket, support arm and turning rollers.

◇ Transferring device

It is comprised of traveling motor, drive gear, transmission shaft and walking wheel. It provides temporary vehicle for the compost turner when changing the groove!

The Reason Why Investors Prefer Groove Type Compost Machine?

Groove type compost making equipment is with least cost among all the organic fertilizer fermentation equipment. Most customers choose it because of the reasonable and affordable price. Comparing with more advanced commercial compost machine which costs manufacturers hundreds of thousands of dollars, the price of groove type machine is more acceptable. It has been sold to countries like USA, CANADA, VIETNAM etc.

PS: If you are operating a large-scale commercial composting facility, Allance will recommend you to choose Full Hydraulic Compost Turner which is designed with hydraulic steering system and crawler traveling system making it easily to compost bulks of materials in short time.

Working Video of Groove Type Compost Turner Machine

Technical Date of Groove Type Commercial Compost Machine

| Model | FJ6000×1050 | FJ6000×350 | FJ4000×1050 | FJ4000×350 |

| Matched power(kw) | 25.74 | 41.5 | 10 | 10 |

| Working speed(m/h) | 50 | 50 | 50 | 50 |

| No-load speed(m/h) | 100 | 100 | 100 | 100 |

| Size of fermentation tank (w×h )mm | 6000×1050 | 6000×350 | 4000×1050 | 4000×350 |

| External dimension (mm) L×W×H | 4670×3920×2740 | 4670×4800×3200 | 4670×3920×2740 | 4700×4800×3200 |

| Lift height of gear(mm) | 1400 | 1500 | 1400 | 1500 |

Technical Date of Hydraulic Groove Type Compost Turner

| Model | XSCSFD03 | XSCSFD04 |

| Power(kw) | 15.5 | 22.75 |

| Working speed(m/h) | 50 | 50 |

| Size of fermentation tank(w*h )mm | 3000×700 | 4000×900 |

| Lift height of mixing gear(mm) | 700-1000 | 800-1100 |

Save

Save

Ace Model 4000 Garbage Disposal Installation Guide

Save